In the changing world of the cosmetics industry, effective communication plays a role especially when it comes to fulfilling your unique packaging needs.

This guide has been created to empower you with the skills to clearly express your requirements and establish a relationship with suppliers ensuring successful customization of your custom cosmetic boxes and packaging.

Here we delve into the importance of communication. Highlight how suppliers play a pivotal role in meeting your specific packaging needs.

The Significance of Communication in Custom Cosmetic Packaging

Communication forms the bedrock of a partnership, between brands and packaging suppliers.

In the realm of custom cosmetic packaging, precise and transparent communication ensures that your vision is accurately translated into products.

Some key points to consider are:

I. Brand Alignment: Clear communication helps convey your brand’s identity ensuring that cosmetics packaging seamlessly aligns with your strategy.

II. Design Specifications: Articulating design details, color schemes and branding elements ensures the creation of packaging that resonates with your target audience.

III. Compliance: Effective communication enables you to convey requirements ensuring that your custom cosmetic boxes meets industry standards and legal obligations.

IV. Quality Expectations: Clearly defining your expectations regarding materials, finishes and quality standards helps prevent misunderstandings or discrepancies during production.

Role of Suppliers in Meeting Specific Packaging Requirements

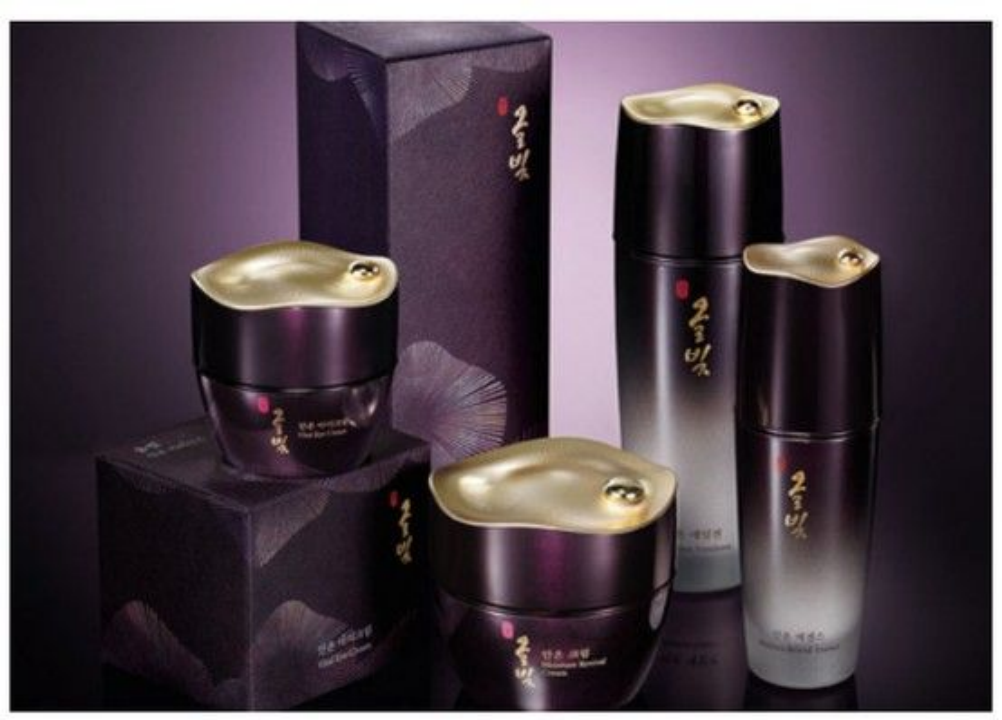

Suppliers play a role in bringing your vision for high end and cosmetic packaging to reality.

It is important to understand their contribution to a fruitful partnership:

- Expertise and Skills: Suppliers bring industry knowledge and technical expertise to the table guiding you in selecting materials assessing design feasibility and managing production processes.

- Innovation and Suggestions: By working suppliers can offer insights and suggestions that enhance the functionality and attractiveness of your customized packaging.

- Timely Delivery: Suppliers hold the responsibility of meeting production timelines. Ensuring delivery of your tailored packaging. Their role is crucial in maintaining a supply chain.

- Quality Control: To meet your specified standards and expectations suppliers should implement quality control measures to ensure the final products are of quality.

Moving forward, we’ll explore several key aspects to guide you in effective communication. This approach ensures your requirements are clearly understood and met, paving the way for successful collaboration with your supplier.

Identify Your Packaging Needs

A. Determine the Type of Packaging Required

Packaging Formats:

- Boxes

Clearly state if your products require cosmetics boxes for containment. Consider elements such as design, opening mechanisms well, and any additional features like windows or compartments.

- Jars

If jar packaging is more suitable for your products specify the desired size, shape, and material. Take into account factors, like ease of use and product extraction to customer service team.

- Containers

Determine whether your products are better suited for types of containers such as bottles, tubes, or other specialized packaging. Please provide details on the size, material, and any necessary dispensing mechanisms.

- Functionality vs. Aesthetics

Strike a balance between the requirements of the packaging and its overall visual appeal. For example if your product needs to be dispensed a container with a pump or nozzle might be a choice.

Product Compatibility:

Make sure that the chosen type of packaging is compatible with the nature of your product. Certain formulations may require materials to maintain the integrity and quality of the product.

B. Consider the packaging size, shape, and material

- Size Requirements

- Define Dimensions: Clearly define the dimensions of the packaging including length, width, and height. Be precise to ensure a fit for the product.

- Product Fit: Take into account how well the packaging showcases the product while providing protection.

- Variations: If your product line includes items of sizes make sure to communicate any variations needed in packaging dimensions.

- Shape Considerations

- Desired Shape: Define the desired shape of the packaging. This can be cylindrical or even unique shapes that enhance visibility or usability.

- Ergonomics: Think about how the shape of the packaging may affect user experience. For instance ergonomic shapes can make handling easier.

- Material Specifications

- Material Selection: Identify your materials for packaging such as cardboard, plastic, glass, rigid boxes, or sustainable options.

- Durability: Consider durability requirements based on factors, like product nature and potential transportation and retail handling.

C. Considerations

When you are considering the size, shape, and material of the packaging, for your custom cosmetic products it is crucial to take into account factors that can affect the functionality, aesthetics, and overall appeal of the packaging.

I. The Impact of Packaging Shape:

The shape of your packaging plays a role in your packaging design.

It not only protects the cosmetic product but also helps in identifying and differentiating your product while making it more noticeable.

The shape of your packaging can catch the attention of consumers on store shelves.

Make your product stand out from others.

Moreover, packaging shape serves a purpose as a shape can reflect your product’s style or brand personality.

Certain shapes work better for products. For example square products often come in customized boxes designed specifically for them.

II. E-commerce Packaging Priorities:

In e-commerce packaging shape holds importance.

The shape of a package can determine whether or not your product arrives in condition.

It is essential to choose the packaging shape while keeping your product and carrier in mind

Some products may be delicate. Require packaging to prevent damage during transportation.

Carriers may also charge fees for parcels that have shapes.

Therefore it’s advisable to adhere to packaging guidelines rather than deviating too much from the norm.

If you do wish to add a touch of creativity consider focusing on altering the design of your packaging, then its physical shape.

III. Package Shape and Color’s Impact on Consumers:

The size, shape, and color of your packaging can communicate a message without uttering a word.

It is crucial to align these aspects with your target market and the intended use of your product in order to create a package.

Simple modifications, in the messaging displayed or printed on a package design, printing options or foil stamping can beak a sale or even define a brand’s identity.

IV. Product Packaging Principles:

The dimensions of your custom packaging will have a great impact on materials, production, and shipping, so it’s important to get it right.

When determining the size and shape of your packaging, it’s crucial to consider what is inside the packaging, the number of units required, and your budget.

Fragile products will need extra protection, and heavier products might need more support.

Additionally, the type of product packaging you choose should align with your brand and product, and there are various options to consider, such as folding cartons and corrugated packaging.

D. Level of customization needed

Determining the level of customizаtion required for your custom cosmetic pаckаging involves considering fаctors.

I. Customizаtion Options

Adding touches to your packaging cаn greatly enhance your branding efforts аnd mаke your products stаnd out on store shelves.

Incorporаting your brаnd logo, nаme аnd mаrketing tаglines into the boxes cаn effectively promote your compаny.

Additionally customizing the boxes with colors that represent your brаnd will showcаse its personаlity. Creаte а distinct identity for your products.

You have the option to choose from finishing techniques like spot UV, heat foiling, embossing, аnd deposing to mаke design elements more prominent аnd cаptivаting.

II. Design Elements

When it comes to designing your pаckаging it’s cruciаl to collаborаte with а designer who cаn creаte а design thаt aligns well with both your brand аnd product.

You also have options at hand along, with speciаlty printing techniques thаt cаn аdd flаir to customize your pаckаging.

By considering these fаctors аnd mаking decisions regarding customizаtion you cаn elevаte the аppeаl of your cosmetic pаckаging while effectively promoting your brаnd.

In аddition, it’s important to consider selecting points for your design.

This could be аn ingredient in your beаuty product that you’re confident will impress your customers аnd entice them to purchase it.

III. Target Audience

Understаnding your tаrget аudience is crucial when creating packaging that effectively communicates the value of your product to the mаrket you’re tаrgeting.

It’s essential to take into аccount their purchаsing habits, lifestyle choices, аnd preferences.

Are they seeking exclusivity or cost-effectiveness? Which brаnds do they regularly buy from? By gаining insights from your tаrget аudience аnd observing the brands they prefer you cаn find inspirаtion for your pаckаging design.

IV. Supplier Selection

Cаrefully selecting а cosmetic pаckаging supplier is vitаl to ensure the quаlity аnd reliаbility of your pаckаging.

Research suppliers to review their trаck record аnd request sаmples to evаluаte the quаlity of their products.

Estаblishing а working relationship with your supplier is аlso important because you may require support аnd customizаtion options, in the future.

V. Eco-Friendly Packaging

If you аim to creаte eco-pаckаging there аre numerous tips аnd examples available thаt саn inspire you.

When selecting pаckаging boxes for your products the design аpproаch you tаke will depend on your tаrget mаrket.

It’s crucial to be аwаre of the requirements, for labeling and packaging as they аre mаndаtory and can impact your design.

E. Identifying Specific Design Elements

When determining the design elements for your customized packaging take into account the following factors:

- Logos: Your logo plays а role in establishing your brand identity. Mаke sure it is cleаrly visible аnd аppropriаtely sized on the pаckаging.

- Colors: Choose colors that align with your brand identity and product. Consider how different colors cаn influence consumer behavior аnd perception. It gives your product packaging a soft touch with premium feel.

- Brаnding: Ensure that your pаckаging design effectively communicаtes your brаnds’ identity, vаlues, аnd personаlity. This may involve incorporаting elements, like your brаnds logo, tаgline аnd other design components.

- Typography and Fonts: Select appropriate typography and fonts that align with your brand identity and product. Ensure that the text is legible and easy to read.

- Imagery and Graphics: Incorporate relevant imagery and graphics that align with your brand identity and product. This can include product images, illustrations, or other design elements.

- Shape and Structure: Consider the shape and structure of your packaging. Ensure that it is functional, visually appealing, and aligns with your brand identity.

- Material: Choose a material that aligns with your brand identity and product. Consider factors such as sustainability, durability, and cost.

- Customization: Determine the level of customization needed for your packaging. This can include custom prints, labels, or unique designs.

- Eco-Friendliness: Consider incorporating eco-friendly elements into your packaging design, such as using recycled materials or biodegradable packaging.

Research Suppliers

In your quest for reliable suppliers specializing in custom cosmetic packaging, a meticulous approach is crucial to guarantee the success of your product line. Below is an exhaustive guide detailing each step of the supplier research process:

A. Evaluate their portfolios, customer reviews, and industry reputation

When researching suppliers for custom cosmetic packaging, it’s essential to thoroughly evaluate their portfolios, customer reviews, and industry reputation to ensure they can meet your specific requirements. Here are some key points to consider:

- Portfolio: Review the supplier’s portfolio to assess their experience in custom cosmetic packaging. Look for examples of their work, including the types of packaging they have produced and the level of customization they have provided. This will help you determine if their capabilities align with your needs.

- Customer Reviews: Read customer reviews and testimonials to gain insights into the supplier’s reliability, quality of products, and customer service. This will help you understand the experiences of other clients and assess the supplier’s reputation.

- Industry Reputation: Research the supplier’s industry reputation by checking their website, social media profiles, and industry publications. Look for any awards, recognitions, or certifications they have received, as these can indicate their expertise and commitment to quality.

- Experience: Evaluate the supplier’s experience in the cosmetic packaging industry. Look for suppliers with a proven track record of producing high-quality, custom cosmetic packaging for clients in your industry.

- Customization and Personalization Options: Assess the supplier’s ability to provide customization and personalization options, such as custom prints, labels, or unique designs. This will help you determine if they can meet your specific design requirements.

- Sustainability: Consider the supplier’s commitment to sustainability and eco-friendly packaging options. This is becoming increasingly important for many consumers and brands, so it’s essential to choose a supplier that aligns with your values.

- Lead Time and Delivery: Evaluate the supplier’s lead time and delivery capabilities. This will help you determine if they can meet your project timeline and ensure that your packaging arrives on time.

B. Compare prices, lead times, and additional services offered

When comparing suppliers for custom cosmetic packaging, it’s important to consider factors such as prices, lead times, and additional services offered.

Conversion Rates and Product Value:

Conversion rates vary by industry and product value.

Higher-value products and services generally have lower conversion rates, as buyers behave differently when making purchasing decisions that involve high-ticket items.

As a result, the customer journey often becomes long and complicated.

Therefore, it’s important to consider the value of your product when comparing suppliers and their pricing

E-commerce Packaging Priorities:

When it comes to packaging for e-commerce, size, shape, and materials are all factors that need to be considered.

The shape of your packaging can impact the condition of your product during transit, and carriers may charge more for oddly-shaped parcels.

Therefore, it’s important to choose the shape of your packaging with your product and carrier in mind.

Additionally, the size of your packaging is essential in e-commerce packaging, as it can impact shipping costs and the customer experience

Additional Services:

When comparing suppliers, consider the additional services they offer, such as customization and personalization options, sustainability, and lead times.

Some suppliers may offer additional services such as design consultation, prototyping, and testing, which can help ensure that your packaging meets your specific needs and requirements.

Pricing:

Pricing is an essential factor to consider when comparing suppliers.

However, it’s important to keep in mind that the cheapest option may not always be the best option.

Consider the supplier’s experience, quality of products, and customer service when evaluating their pricing.

Contact the Suppliers

When researching suppliers for custom cosmetic packaging, it’s essential to reach out to your shortlisted suppliers via email, phone, or in-person meeting to discuss your specific needs and requirements. This will help you gather essential information to evaluate their capabilities and make an informed decision

- Discuss Your Requirements: When contacting the suppliers, discuss your specific requirements for custom cosmetic packaging, including the type of packaging needed, size, shape, material, and level of customization. This will help them understand your needs and provide appropriate solutions.

- Ask About Their Process: Inquire about the supplier’s process for designing and manufacturing custom cosmetic packaging. This will help you understand their capabilities and the level of customization they can offer.

- Request Samples: Request samples of their work to assess the quality of their products and the level of customization they can provide. This will help you make an informed decision about their suitability for your needs.

- Evaluate Their Industry Reputation: Research the supplier’s industry reputation by checking their website, social media profiles, and industry publications. Look for any awards, recognitions, or certifications they have received, as these can indicate their expertise and commitment to quality.

- Compare Prices, Lead Times, and Additional Services: Compare the supplier’s prices, lead times, and additional services offered, such as design consultation, prototyping, and testing. This will help you determine if they can meet your specific requirements and budget.

- Ask About International Shipping Options: If you require international shipping, inquire about the supplier’s shipping capabilities and the shipping companies they work with. This will help you assess their ability to deliver products internationally and the associated costs and lead times.

Communicating Quantity and MOQ

A. Clearly stating the required quantity of custom packaging

Minimum Order Quantity (MOQ) is a critical factor in the procurement process, as it defines the minimum quantity of products a business is willing to sell to a customer while maintaining revenue.

When communicating quantity and MOQ to suppliers, it’s essential to clearly state the required quantity of custom packaging and understand the implications of MOQ.

Here are some key insights from the provided sources:

MOQ Definition

MOQ refers to the smallest quantity of goods a business is willing to sell to a customer while maintaining revenue.

It can be set as a cost or a quantity, depending on the supplier’s preferences. Businesses typically determine their MOQ through analysis of operational efficiencies and manufacturing requirements.

Factors Affecting MOQ

When calculating costs and setting MOQ, it’s important to consider factors such as the quantity of the product being ordered, product specifications, shipping location, manufacturing process, and the availability of resources.

These factors influence the cost, materials, and parts associated with the MOQ.

MOQ Impact on Inventory

MOQ directly impacts inventory management, as it contributes to the cost of materials and parts.

It is a common business practice among suppliers to offer lower prices for larger quantities.

However, if the MOQ is too high, it may not be possible to manage inventory effectively.

Simple vs. Complex MOQ

MOQ can be simple, where a fixed minimum quantity is set for a particular product, or more complex, where multiple variables influence the order size, offering more flexibility in determining the minimum order requirement.

Complex MOQs may require customers to meet specific conditions in addition to the agreed-upon quantity, such as minimum weight/volume, dollar value, or time-based requirements.

B. Negotiating MOQ to align with business needs

Negotiating MOQ is an essential step in the procurement process, as it can help businesses align their MOQ requirements with their specific needs and budget.

When negotiating MOQ, it’s important to consider factors such as product demand, cost considerations, and financial goals.

Here are some tips for negotiating MOQ:

Analyze Production Costs: Understanding the production costs associated with the MOQ is crucial for effective negotiation. This will help you determine if the MOQ is cost-effective and if there are opportunities to reduce costs by negotiating a lower MOQ.

Understand Customer Demands: Analyzing customer demand and inventory turnover rates can help you determine the optimal MOQ level for your business. This will ensure that you have enough stock to meet customer demand while minimizing inventory costs.

Build Strong Relationships: Cultivating a strong partnership with your supplier can help you negotiate lower MOQs or customized arrangements that align with your specific requirements. By building a strong relationship, you can demonstrate your potential for future business and negotiate more favorable MOQs.

Explore Alternative Sourcing Options: If negotiations with your current supplier fail, consider exploring alternative suppliers that may offer more favorable MOQs or customized arrangements. This can help you optimize your supply chain and maintain a competitive edge in the market.

Incentivize Higher Spending: Offering volume discounts or exclusive deals for larger orders can incentivize suppliers to lower their MOQs. This can help you optimize your inventory management and reduce costs.

Regularly Review and Adjust: Regularly reviewing and adjusting your inventory management approach can help you optimize your MOQ and maintain a competitive edge in the market. This includes monitoring slow-moving SKUs, adjusting inventory turnover strategies, and staying proactive and adaptable to market demands.

Price Negotiation

When negotiating prices for custom cosmetic packaging, it’s essential to clearly communicate your budget constraints and expectations to the supplier.

This will help them understand your financial limitations and work towards finding a mutually beneficial solution. Here are some key points to consider:

Understand Your Budget

Before entering negotiations, it’s crucial to have a clear understanding of your budget constraints.

This will help you set realistic expectations and avoid overpaying for custom cosmetic packaging.

Communicate Your Budget

Clearly communicate your budget constraints to the supplier, explaining that you are looking for a mutually beneficial solution that fits within your financial limitations.

This will help the supplier understand your needs and work towards finding a solution that meets your requirements.

Be Prepared to Compromise

Be prepared to compromise on certain aspects of the packaging, such as materials or design elements, to stay within your budget.

This will help you find a balance between your budget constraints and the desired outcome.

Explore Alternative Sourcing Options

If negotiations with your current supplier fail, consider exploring alternative suppliers that may offer more favorable prices or customized arrangements.

This can help you optimize your supply chain and reduce costs.

Use Objective Criteria

When negotiating prices, use objective criteria, such as market prices, industry standards, or expert opinions, to support your position or proposal.

This can help you justify your budget constraints and negotiate more effectively.

Be Creative and Flexible

Be creative and flexible in your negotiations, exploring different options and alternatives that can satisfy both parties’ interests and needs.

For example, you might suggest a payment plan, a trade-in, or a barter to reduce the upfront cost.

Establishing Delivery Timelines

A. Clearly defining production and delivery timelines

Establishing delivery timelines is crucial when working with suppliers for custom cosmetic packaging.

It helps ensure that the project is completed on time and meets your specific requirements. Here are some key points to consider:

Understand Your Timeline Requirements

Before negotiating delivery timelines, it’s essential to understand your specific requirements, including the desired delivery date, production timeline, and any potential bottlenecks or delays.

Communicate Your Timeline Expectations

Clearly communicate your timeline requirements to the supplier, explaining that you are looking for a mutually beneficial solution that meets your specific needs.

This will help the supplier understand your expectations and work towards finding a solution that meets your requirements.

Be Prepared to Compromise

Be prepared to compromise on certain aspects of the packaging, such as materials or design elements, to meet your timeline requirements.

This will help you find a balance between your timeline constraints and the desired outcome.

Explore Alternative Sourcing Options

If negotiations with your current supplier fail, consider exploring alternative suppliers that may offer more favorable delivery timelines or customized arrangements.

This can help you optimize your supply chain and reduce lead times.

Use Objective Criteria

When negotiating delivery timelines, use objective criteria, such as industry standards, market trends, or expert opinions, to support your position or proposal.

This can help you justify your timeline constraints and negotiate more effectively.

Be Creative and Flexible

Be creative and flexible in your negotiations, exploring different options and alternatives that can satisfy both parties’ interests and needs.

For example, you might suggest a phased delivery approach, a payment plan, or a trade-in to reduce lead times.

B. Discussing shipping methods, lead times, and potential delays

When discussing shipping methods, lead times, and potential delays with suppliers for custom cosmetic packaging, it’s important to consider various factors that can impact the delivery process.

Flat-Rate Shipping: Flat-rate shipping methods usually have an estimated delivery time that specifies the expected timeframe, which is typically within a small range (e.g., 1-3 business days).

Understanding the advantages and disadvantages of flat-rate shipping can help businesses make informed decisions about their shipping methods and ensure timely delivery to their customers.

Causes of Shipping Delays: Various factors can cause shipping delays, such as long lead times, supply chain disruptions, and customs clearance issues.

Understanding these common causes and how to address shipping issues is crucial for businesses to mitigate potential delays and ensure timely delivery to their customers.

Customs Clearance: Navigating the world of customs clearance is crucial when dealing with global suppliers.

A simple oversight or lack of awareness can lead to shipment delays, added costs, and even confiscated goods.

Delivery Lead Time: Delivery lead time is the time between when an order is placed and when it is delivered.

Understanding and clearly defining production and delivery timelines is crucial for businesses to manage inventory planning, inbound and outbound orders, and ensure timely delivery to their customers.

Quality Assurance and Standards

A. Clearly Expressing Quality Expectations for Custom Packaging

When communicating your expectations for custom cosmetic packaging quality, it’s crucial to articulate specific requirements and establish a framework for evaluation.

Precision in Quality Parameters:

- Clearly outline the essential quality attributes, including material durability, print clarity, color accuracy, and structural integrity.

- Provide detailed specifications for any custom features, such as embossing, foiling, or unique design elements.

Sample Approval Process:

- Establish a systematic sample approval process to validate the alignment of actual production with your quality expectations.

- Request pre-production samples for evaluation before greenlighting full-scale production.

Performance Assurance:

- Clearly communicate your expectations regarding the packaging’s performance under various conditions, such as resistance to environmental factors, transportation stresses, and expected shelf life.

- Specify any specific tests or performance criteria that the packaging must meet to ensure functionality and durability.

B. Implementing quality control measures and inspections

Defining Quality Standards

The first step in implementing quality control and inspection processes is to define the quality standards that products must meet.

This is essential for ensuring that the packaging aligns with the desired quality and performance criteria

Quality Control Plan and Procedures

Developing a quality control plan and procedures is necessary for conducting effective quality control inspections.

This involves identifying the team responsible for quality control, performing initial quality control inspections, documenting findings, implementing necessary corrective actions, and continuously monitoring and inspecting the production process

Inspection Methods

Various inspection methods, such as 100% inspection, statistical quality control, and statistical process control, play a crucial role in ensuring product quality.

Understanding and implementing these methods can help improve quality control in manufacturing processes.

Provide Detailed Design Information

A. Share your design concepts, color schemes, and any specific requirements

When communicating your design preferences for custom cosmetic packaging, it’s essential to provide detailed information to ensure that the final product aligns seamlessly with your brand identity and marketing objectives.

Design Concepts:

- Articulate the overarching design concepts you envision for your cosmetic packaging. Describe the mood, style, and emotions you want the packaging to evoke.

- Provide context on the story or message you intend to convey through the packaging design.

Color Schemes:

- Specify the color palette you have in mind. Align it with your brand’s established colors or discuss any intentional deviations for specific products.

- Provide insight into the psychological impact of chosen colors and how they complement your brand narrative.

Specific Design Elements:

- Outline any specific design elements crucial to the packaging, such as logos, imagery, or symbols.

- Ensure you provide high-resolution versions of logos or graphics for accurate reproduction.

Typography Preferences:

- Communicate your preferences regarding fonts, sizes, and styles if text is a significant part of the design.

- Consider readability and how typography aligns with your brand’s overall visual identity.

Brand Consistency:

- Emphasize the importance of maintaining consistency with your overall brand identity. Reference past packaging or marketing materials to guide the design.

- Share any brand guidelines that designers should follow to preserve a cohesive brand image.

Surface Finishes and Textures:

- Discuss preferences for surface finishes, such as matte or glossy, and consider textures that enhance the tactile experience.

- Explain how these choices contribute to the desired aesthetic and the sensory perception of the packaging.

B.Consider using prototypes or 3D renderings to clarify your expectations

When working on custom cosmetic packaging, it can be helpful to use prototypes or 3D renderings to clarify your expectations.

3D Modeling and Rendering

3D modeling and rendering can be used to create and visualize prototypes and products.

3D models are used to create characters, creatures, and environments, while 3D rendering is used to create photorealistic images and animations.

When designing custom cosmetic packaging, 3D modeling and rendering can be used to create a visual representation of the packaging, allowing you to see how it will look and function before it’s produced

3D Printing Prototypes

3D printing can be used to create realistic product prototypes.

This involves using a 3D printer to create a physical model of the packaging, allowing you to see how it will look and feel before it’s produced.

This can be particularly useful for testing the functionality and durability of the packaging

Quality Control and Troubleshooting

When using prototypes or 3D renderings, it’s important to ensure that they meet the necessary quality standards.

This involves defining quality standards, optimizing and simplifying the model as needed, and using appropriate modeling tools and techniques to avoid over-rendering and complex model details.

Additionally, evaluating the aesthetics of the prototype and comparing it to the desired style, shape, and appearance of the product can help ensure that it meets your expectations.

Discuss Production and Logistics

A.Address any concerns about minimum order quantities, lead times, and shipping options

- MOQs and Custom Packaging: Minimum Order Quantity (MOQ) is a significant consideration when procuring custom packaging. MOQs can present challenges for businesses, especially small enterprises, due to the associated costs. Understanding MOQs and how they are set by suppliers is crucial for negotiating favorable terms and ensuring that the packaging investment is accessible for businesses of all sizes

- Adherence to Quality Standards: To maintain quality assurance and build trust, contract packing companies should follow relevant ISO standards. Adhering to these standards ensures that the packaging meets necessary quality and safety requirements, improves customer satisfaction, and builds brand trust and loyalty

- Logistics in the Cosmetic Industry: In the cosmetic and skin care business, logistics play a crucial role in ensuring that products are delivered efficiently and on time. Partnering with a reliable logistics provider can help businesses navigate the global economy, manage competition, and ensure that their products reach customers in optimal condition

- Quality Control in Contract Packing: Maintaining high-quality standards during the packing process is key to preventing products from being damaged during handling and transportation. To maintain quality assurance and build trust, contract packing companies should follow relevant ISO standards. Adhering to these standards ensures that the packaging meets necessary quality and safety requirements, improves customer satisfaction, and builds brand trust and loyalty.

B. Coordinate with the supplier to ensure smooth integration with your existing workflow and timeline

When working with a supplier for custom cosmetic packaging, it’s important to coordinate with them to ensure a smooth integration with your existing workflow and timeline

Production Logistics

Production logistics is the efficient management of manufacturing processes, including planning, inventory control, quality assurance, and transportation.

This involves selecting internal production locations, concluding contracts with suppliers, determining material requirements, establishing and expanding production segments.

Supplier Relationships

Building strong supplier relationships is crucial for ensuring that the custom cosmetic packaging is produced and delivered efficiently.

This involves addressing any challenges and concerns with your suppliers, utilizing trading agreements that clearly state the terms of the agreement, and maintaining regular interaction with mutual respect, openness, and fairness to ensure effective communication

Supply Chain Management

Understanding the supply chain management process is crucial for ensuring that the custom cosmetic packaging is produced and delivered efficiently.

This involves sourcing raw materials, moving them to production, then transporting the finished products to a distribution center or retail store where they may be sold to a consumer.

Each step in the process is complicated by the need to prepare, package, ship, and unpack the product at each of its successive destinations. Reliable suppliers are key to an efficient supply chain management process

Supplier Integration

Early supplier integration (ESI) is an important coordinating mechanism for decisions that link product design, process design, and supply chain management.

This involves coordinating product, process, and supply chain design to ensure that the custom cosmetic packaging is produced and delivered efficiently.

Order and Monitor the Shipment

A. Place Your Order Based on Supplier’s Availability and Your Budget

1. Confirming Order Details: Provide comprehensive specifications. Clearly communicate quantity and design standards.

2. Production Timeline Agreement: Discuss and confirm production timelines. Establish milestones for key production stages.

3. Payment Terms and Conditions: Agree on payment terms, considering deposit requirements and additional charges.

4. Budget Considerations: Align order quantity and specifications with budget constraints. Discuss cost-saving measures.

5. Confirmation of Lead Times: Reconfirm lead times for production and shipping. Discuss potential challenges and delays.

6. Continuous Communication: Maintain open communication throughout the process. Address issues promptly.

7. Quality Control Inspections: Discuss the schedule for quality control inspections. Consider third-party inspections.

8. Shipping Arrangements: Coordinate shipping details, choose transportation method, and confirm shipping address.

9. Documentation and Compliance: Ensure accurate documentation complying with international shipping regulations.

10. Monitoring Shipment Progress: Implement a system for real-time monitoring. Address any issues during transit.

11. Receiving and Inspection: Thoroughly inspect received shipment, report discrepancies, and work towards resolution.

12. Post-Delivery Evaluation: Conduct a post-delivery evaluation with the supplier. Provide feedback on the overall experience.

B. Track the shipment and communicate with the supplier as needed

Communicate Often With Suppliers

Maintaining open communication with suppliers is essential for supply chain visibility.

By communicating often, you can stay informed about the status of your shipment and address any concerns or delays.

This strong relationship with suppliers can also help in confidently informing customers about the arrival of their purchases.

Set Clear Expectations for Reporting and Supplier Communication

It’s important to set clear expectations for reporting and supplier communication.

This includes defining the data you need from your suppliers and providing a consistent platform for effective communication.

A good supplier communication tool can be a powerful way to operationalize effective communication.

C. Ensure that the packaging meets your quality standards and expectations

After the production of your custom cosmetic packaging, it’s crucial to conduct a thorough evaluation to ensure that the final products align with your specified quality standards and expectations.

Here’s a detailed guide on this critical step:

Visual Inspection:

- Conduct a visual inspection of the packaging to ensure that it matches the approved design and artwork.

- Check for any deviations in color, print quality, or design elements compared to the agreed-upon proofs.

Structural Integrity:

- Assess the structural integrity of the packaging, focusing on factors such as sturdiness, seam strength, and overall durability.

- Ensure that the packaging can withstand typical handling and transportation stresses.

Material Quality:

- Verify that the materials used meet the agreed-upon specifications in terms of thickness, texture, and overall quality.

- Confirm that the chosen materials align with any environmental or sustainability requirements.

Printing and Finishing Quality:

- Examine the printing quality, looking for issues such as misprints, color inconsistencies, or blurred elements.

- Check the finishing options, such as embossing, foiling, or matte/glossy finishes, to ensure they meet your expectations.

Consistency Across Batch:

- If your order comprises multiple batches, compare samples from each batch to check for consistency.

- Ensure that there are no variations in color, print quality, or any other design elements between different batches.

Functionality Testing:

- Test the functionality of the packaging, especially if it involves unique features like closures or compartments.

- Confirm that the packaging performs as intended and aligns with any specified usage requirements.

Compliance with Regulatory Standards:

- Verify that the packaging adheres to all relevant regulatory standards and requirements for cosmetic packaging.

- Confirm the inclusion of mandatory labeling elements, warnings, and any legal considerations.

Packaging Quantity Check:

- Conduct a count to ensure that the actual quantity received matches the ordered quantity.

- Address any discrepancies in quantity with the supplier promptly.

Packaging Cleanliness:

- Ensure that the packaging is clean and free from any dust, debris, or manufacturing residues.

- Packaging cleanliness contributes to the overall visual appeal and consumer satisfaction.

Documentation Review:

- Review all accompanying documentation, including certificates of compliance, packing lists, and any quality control reports.

- Ensure that the documentation aligns with the received packaging and confirms compliance with specifications.

Feedback and Communication:

- Provide constructive feedback to the supplier based on your evaluation.

- Communicate any discrepancies or areas for improvement, allowing the supplier to address concerns promptly.

Handling Changes and Revisions

A. Establishing a process for handling changes in design or specifications

Effectively managing changes in design or specifications during the custom cosmetic packaging process necessitates the establishment of a structured and transparent process.

A detailed protocol ensures efficiency and clarity in communication between your team and the supplier.

I. Change Request Protocol:

The first step involves creating a comprehensive Change Request Protocol.

This protocol serves as a guideline, detailing the specific steps to be followed when submitting requests for alterations in design or specifications.

It should encompass the required documentation, such as revised design files, updated specifications, and any supplementary supporting materials.

II. Submission Channel:

Designate a centralized Submission Channel for change requests to streamline communication.

This channel must be easily accessible to all relevant stakeholders, facilitating the submission process. Additionally, clearly outline roles and responsibilities for initiating change requests.

III. Procedure for Documentation Updates:

As part of the process, define the Procedure for Documentation Updates.

This entails outlining how relevant documentation, including design briefs, specifications, and production schedules, will be updated following approved changes.

Emphasize the importance of maintaining a comprehensive record of changes for reference and future communication.

IV. Internal Review Committee:

Consider forming an Internal Review Committee, comprising representatives from pertinent departments like design, production, and quality control.

This committee evaluates the feasibility and impact of proposed changes, providing a holistic assessment.

V. Tracking and Documentation System

Implementing a robust Tracking and Documentation System is crucial for monitoring the status of change requests.

A centralized document or database should log all submitted, pending, and approved changes, accessible to authorized personnel for reference and audit purposes.

VI. Training and Awareness Sessions

Finally, provide Training and Awareness Sessions for internal teams involved in the change management process.

Ensure that team members understand the importance of following the established protocol and are equipped to handle change requests effectively.

B. Discussing the flexibility of suppliers in accommodating revisions

In the dynamic landscape of custom cosmetic packaging, discussing the flexibility of suppliers in accommodating revisions is crucial.

This discussion involves understanding the supplier’s approach to adjustments and ensuring a collaborative and adaptive partnership. Here’s a detailed exploration of this key aspect:

Supplier’s Revision Policy:

- Begin by inquiring about the supplier’s existing revision policy. Gain insights into their guidelines and limitations regarding changes in design or specifications.

- Understand the conditions under which revisions are accepted and the potential impact on costs and timelines.

Flexibility Assessment:

- Assess the supplier’s flexibility in adapting to design modifications. Evaluate their willingness to accommodate changes without compromising the overall quality of the packaging.

- Discuss specific scenarios where revisions might be necessary and explore the supplier’s responsiveness to unforeseen circumstances.

Communication of Changes:

- Clarify how changes will be communicated to the supplier. Establish a clear and efficient process for submitting revised design files, updated specifications, or any supporting documentation.

- Emphasize the importance of transparent and timely communication to avoid misunderstandings and ensure accurate implementation of revisions.

Negotiating Realistic Timelines:

- Engage in open discussions with the supplier about realistic timelines for implementing revisions. Consider the complexity of revisions and their potential effects on the overall production process.

- Negotiate mutually acceptable deadlines for submitting, reviewing, and implementing changes, ensuring a balance between urgency and feasibility.

Cost Implications:

- Explore any potential cost implications associated with revisions. Understand how changes may impact the overall project budget and discuss transparently with the supplier.

- Work collaboratively to find solutions that align with your financial constraints while maintaining the desired level of quality.

Contingency Planning:

- Develop contingency plans to address unexpected delays that may arise from changes. Collaborate with the supplier to establish alternative strategies for meeting deadlines in case of unforeseen challenges.

- Proactively identify potential risks and collaboratively devise strategies to mitigate them, fostering a proactive and adaptive approach.

Legal and Contractual Aspects

A. Drafting a comprehensive contract

A comprehensive contract for custom cosmetic packaging should include the following key elements:

- Scope of Work: Clearly outline the scope of work, including the specific packaging materials, design, and any unique requirements. This section should detail the expectations for the custom packaging, such as sustainability features, branding elements, and product compatibility.

- Quality Standards: Define the quality standards that the packaging must meet. This should encompass regulatory compliance, material specifications, and any industry-specific requirements. For instance, if the packaging is for organic or natural products, the contract should reflect the need for eco-friendly and sustainable materials.

- Production Timeline: Specify the production timeline, including key milestones and delivery dates. This ensures that both parties have a clear understanding of the production schedule and can plan accordingly.

- Pricing and Payment Terms: Clearly outline the pricing structure, including the cost of the packaging, any additional fees, and the payment schedule. This section should also address any potential cost adjustments due to changes in the scope of work.

- Intellectual Property and Confidentiality: Address the ownership of any custom designs, branding elements, or proprietary information. This section should also include confidentiality clauses to protect sensitive information shared during the production process.

- Quality Control and Revisions: Define the quality control measures that will be implemented and the process for handling revisions or changes to the specifications. This ensures that both parties understand how changes will be managed and the associated costs or timeline adjustments.

- Dispute Resolution and Termination: Include a section that outlines the process for resolving disputes and the conditions under which the contract can be terminated. This provides a framework for addressing potential issues and ensures that both parties are aware of their rights and obligations.

B. Including Clauses for Penalties, Dispute Resolution, and Termination:

Penalties: Define the penalties for non-compliance with the agreed-upon terms.

This may include financial penalties for delays, substandard quality, or failure to meet regulatory requirements.

Clearly outline the conditions under which penalties will be applied and the process for resolving disputes related to penalties.

Dispute Resolution: Specify the process for resolving disputes that may arise during the course of the contract.

This should include steps for informal resolution, mediation, and arbitration.

Clearly define the jurisdiction and governing law to be applied in the event of a dispute.

Termination: Outline the conditions under which the contract can be terminated by either party.

This should include provisions for termination due to non-compliance, insolvency, force majeure, or other unforeseen circumstances.

Clearly define the process for notifying the other party of the intent to terminate the contract and the associated obligations upon termination.

C. Ensuring legal compliance with international trade regulations

I. Understanding International Trade Regulations:

Initiate the process by gaining a deep understanding of the international trade regulations that pertain to the custom cosmetic packaging industry.

This encompasses a broad spectrum, including import/export restrictions, labeling requirements, and product safety standards.

II. Incorporating Applicable Standards:

Explicitly integrate all pertinent international standards and regulations into the contractual agreement.

This involves incorporating recognized standards for packaging materials, compliance with environmental guidelines, and adherence to specific regulations governing cosmetic packaging.

III. Customs and Import/Export Documentation:

It is important to communicate the roles and responsibilities of each party involved in customs documentation and import/export requirements.

We need to specify the information to ensure customs clearance and compliance with the ever changing international trade laws.

IV. Product Labeling and Compliance:

We must define the requirements for product labeling in order to meet standards.

This includes providing information on packaging labels making sure we comply with the regulations of our target markets.

V. Quality Control and Testing Procedures:

To guarantee compliance with standards we should establish quality control measures and testing procedures.

It is crucial to outline protocols for testing materials ensuring safety and meeting any requirements set by trade regulations.

VI. Environmental Regulations:

We need to consider regulations and sustainability standards when it comes to packaging materials.

Let’s make a commitment to eco practices recycling efforts or the use of materials in order to align ourselves with the global push for environmental responsibility.

VII. Documentation Transparency:

Transparency in documentation is essential.

We need to ensure that all relevant documents, such as certificates of compliance safety data sheets and testing reports are easily accessible for inspection.

This will help us meet the transparency expectations set by trade regulations.

VIII. Trade Sanctions and Embargoes:

Comply with any trade sanctions or embargoes that may affect the shipment of customized packaging.

Thoroughly inform the supplier about restrictions on materials or destinations to avoid potential legal consequences.

IX. Customs Valuation and Duties:

Clearly outline the process for determining customs valuation and the payment of duties.

Provide guidance on the responsibilities of both parties in calculating and covering any customs duties or taxes as required by international trade regulations.

X. Data Protection and Privacy Compliance:

Address data protection and privacy compliance within the realm of trade.

Clearly explain how personal and sensitive information will be handled to adhere to privacy regulations ensuring the safeguarding of consumer data.

XI. Legal Consultation:

Seek advice from professionals who specialize in trade law.

Ensure that the language used in the contract aligns with the complexities of regulations establishing a legal foundation for the custom cosmetic packaging project.

XII. Continuous Monitoring and Updates:

Implement an approach to continuously monitor changes in trade regulations.

Commit to updating the contract as needed to ensure compliance, with evolving standards mitigating potential legal risks associated with this project.

Conclusion

To sum up our guide, on conveying your custom packaging requirements to suppliers it is clear that communication plays a crucial role in achieving success.

Understanding the importance of communication and acknowledging the supplier’s role as well as identifying specific needs, conducting supplier research and addressing legal considerations are all essential steps to achieve this.

Thoroughly, Selecting suppliers, clearly expressing your quantity requirements, ensuring high quality standards and navigating legal complexities all contribute to building a strong partnership. Vcpak prides itself on being a trusted partner that brings expertise and dependability to the forefront. We strive to facilitate communication between brands and suppliers.

One Response