The packaging industry is full of innovation because of the creative thinking of the packaging suppliers. They do not only manufacture packaging designs that charm the consumers with their aesthetics but also ensure that the packages are functional and offer a premium experience to the consumers.

One of the packaging innovations is UV Coating on the packaging labels, boxes, flyers, vouchers, and cards. Available in several types, UV coating adds a superior finish to cosmetic packaging.

This finish makes the product packaging designs appealing and also helps the primary packaging protect the contents of the cosmetic jars from UV rays. So, if you want to know about the process of UV packaging, how it works, its types, and its benefits.

What is UV Coating?

As the name implies, UV coating is the type of coating in which UV radiation is used to add final touches to the packaging material.

Being one of the prominent types of cosmetic packaging coatings, it provides an additional layer of protection to cosmetic packaging boxes, gift cards, labels, and anything made of paper or cardboard.

There are several types of UV coating including glossy UV coating, matte UV coating, spot UV coating, and soft-touch UV coating.

UV Coating Process

Below are the basic steps of how UV coating is done to help you understand the process.

- First of all, a clear solution of chemicals like polyethylene, calcium carbonate, and kaolinite is made.

- This clear compound solution is then refined through processing and viscosifers are added in the refined solution. The role of the viscosifers is to help the chemical solution attach to the packaging paper strongly.

- Once the final solution is ready, a silkscreen or roller is used to apply that solution to the pre-printed product packaging.

- After the chemical coating is equally distributed over the packaging paper, it is placed under UV light that allows it to cure and dry instantly.

Also, note that UV Coating is done on one, two, or all sides of the packaging. So, you have to cure each side of cosmetic cream jars separately.

Purpose of UV Coating

You might be considering UV packing for its aesthetic appeal. But there is a lot more to it. We will discuss the benefits of UV coating below.

Providing a Layer of Protection to Paper Packaging

Paper or cardboard packaging alone can be flimsy and prone to damage caused by environmental factors like moisture and scratches. Curing the chemical solution under UV rays creates a strong layer of protection on your cosmetic cream jars.

Not only does it protect the cosmetic packaging from wear and tear but it also prevents the degradation of the product due to UV rays. Additionally, It is especially beneficial to color cosmetics that generate over 2.3 billion dollars in sales because UV coating packaging makes the original shade clear.

Adding to the Aesthetics of Custom Cosmetic Packaging Designs

As UV coating comes in multiple types, it adds to the beauty of custom cosmetic packaging. Whether you want to make the eyes of your consumers shine with gloss UV packaging or enhance the artistic design by adding texture to it with matte UV coating, UV coating can do it all for you.

A Cost-Economic Solution to Enhance Packaging Durability

Usual primary and secondary product packaging is often scratched during transport and storage making the products look older than they are. In such cases, lamination or UV coating is used.

Although lamination improves the durability of cosmetic packaging, it is expensive when compared to UV coating. Thus, UV coating provides a cost-effective alternative to increase the durability of product packaging.

Types of UV Coating

While we are only going to focus on the 2 major types of UV coating used in skincare and beauty packaging, there are 4 types of UV coating.

These are given as,

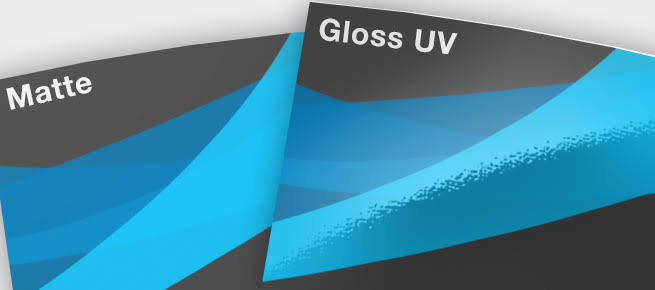

1. Gloss UV Coating

Gloss UV coating is the type of coating in which the surface of the cosmetic packaging is reflective. It shines and reflects light as you move the container. High gloss UV coating is used for premium products to enhance the visual appeal of the packaging and make it stand out from the rest of the product line.

2. Matte UV Coating

For minimalist brands, UV gloss coating does not always go well with the concept behind the brand. Thus, matte UV coating comes into play. In matte UV coating, the surface of the cosmetic packaging is neither shiny nor does it reflect the light.

However, it gives a texture to the surface and makes it appear luxurious.

3. Spot UV Coating

Just as the name implies, there are only a few spots or patterns of UV coating in spot UV coating. This type of UV coating is used to add details to the art and design of the product packaging.

Furthermore, it can be used to highlight the product name, brand logo, or specific information about the product.

4. Soft Touch UV Coating

Soft touch UV coating provides a satin finish to the cosmetic containers just like matte UV coating. However, the main point of this type of UV coating is the tactile experience.

It feels soft and smooth to the touch and enhances customer experience. Many high-end brands use soft-touch UV coating to allure their consumers by stimulating their tactile sensations.

Why Choose Gloss UV Coating for Cosmetics Packaging?

Gloss UV coating is compatible with almost every type of product and it can make the product stand out on the shelves. Furthermore, here are the reasons why you should choose gloss UV coating for cosmetics packaging.

1. Offers a Beautiful Glossy Sheen

Let us put ourselves in the shoes of your target audience for a while. Imagine you go to a skincare and makeup store where there are unlimited products and you barely know anything about cosmetics.

Many products have dull packaging while a few shine bright. Now, which one would you prefer? The glossy ones, right? Well, Gloss UV coating provides a beautiful and irresistible sheen to the primary and secondary cosmetic packaging.

Furthermore, using spot gloss UV packaging makes the design of the boxes more prominent and adds to the aesthetics.

2. Smooth to Touch for a Pleasant Experience

Any random product packaging made of low-quality paper or cardboard feels rough to the touch. Not to mention, it can also turn off the consumers instantly as it looks cheap.

In contrast, UV gloss coating provides a smooth layer on the cosmetic packaging. It gives the cosmetic container and its box a sleek appearance. Furthermore, it is smooth to the touch and offers a pleasant experience to the consumers.

As UV coating is also added to the brand cards, gift cards, and vouchers, it can enhance the overall image of the brand.

3. Resists Abrasions, Scratches, and Smudging

UV gloss coating is not only shiny but it also ensures that nothing dulls that shine. Custom cosmetic jar packaging without UV coating gets scratches and abrasions during its transport or even storage.

Additionally, the cosmetic packaging design smudges over time. Gloss UV coating is resistant to abrasions, scratches, and smudging. Thus, you do not have to worry about the customers’ complaints after seeing damaged packages.

Why Choose Matte UV Coating for Cosmetics Packaging?

Glossy UV packaging has been popular for quite a while. However, matte

1. Offers a Premium, Refined Look

Just like glossy lipsticks and lip glosses are great for everyday life and you look for matte lip colors on important occasions, matte UV packaging is more compatible with high-end products.

This is because the flat matte-UV coating is as durable as glossy UV coating yet it gives the cosmetic jars a more sophisticated, refined, and luxurious look.

2. Clear Vibrant Printing and Non-Reflective

As we explained earlier, matter UV packaging is non-reflective. Now, the benefits of this non-reflection can be explained by the fact that fingerprints become apparent in gloss UV packaging while matte UV packaging always looks untouched.

Furthermore, it makes the deeper and darker colors like brown, black, blue, plum, and more look vibrant and clear.

3. Softer, Velvety Feel

Synonymous with metallic plastic, matte UV coating is as sturdy as metal yet is as soft to the touch as plastic. Therefore, it provides a satin finish to the cosmetic containers.

Moreover, the layer of matter UV coating has the same thickness and durability as that of the gloss UV coating. However, its overall looks and tactile sensations give a velvety feel.

Conclusion

To kill two birds with 1 stone in the cosmetic packaging industry, UV coatings on cosmetic boxes, cards, and vouchers are used. They protect the cardboard and paper packaging from damage while making it look charming.

We discussed the two main types of UV coatings in this article and both have different uses. So, whether you want to give your cosmetic containers a glossy sheen or a matte finish, Contact VCPAK for the best services.